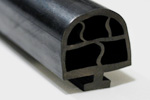

In association with our distributor International Track Systems, Arc Rubber has developed a rail seal for use where road surfaces cross a rail line. The seals are designed to create a smooth crossing for auto traffic, as well as reduce the impact and vibration the road surface encounters from train traffic. Constructed from a high quality EPDM, ensuring years of durability, all components are made right here in our factory, supporting the US economy. Installation can occur in two ways. First, spikes can be used to nail the seal into place. The second option is to use our CamClamps. These clamps have been designed for speedy installation, and with the installer in mind. Using our supplied tool while in a standing position, a quarter turn installs the clamp and produces incredible grip strength. Find more information at www.RailSeal.com or call 724-658-5970.

In association with our distributor International Track Systems, Arc Rubber has developed a rail seal for use where road surfaces cross a rail line. The seals are designed to create a smooth crossing for auto traffic, as well as reduce the impact and vibration the road surface encounters from train traffic. Constructed from a high quality EPDM, ensuring years of durability, all components are made right here in our factory, supporting the US economy. Installation can occur in two ways. First, spikes can be used to nail the seal into place. The second option is to use our CamClamps. These clamps have been designed for speedy installation, and with the installer in mind. Using our supplied tool while in a standing position, a quarter turn installs the clamp and produces incredible grip strength. Find more information at www.RailSeal.com or call 724-658-5970.

Arc Rubber provides industrial businesses with a wide range of quality, cost-effective rubber products with a quick turnaround for customers. We utilize an extensive lineup of production equipment to extrude your small, delicate parts in continuous lengths, as well as products as large as 12 inches in width and 10 feet in length. Molding presses complete our manufacturing lineup. Through the integration of our in-house tool shop, we are able to expertly manufacture new tooling and quickly alter your existing profiles to address sudden design modifications. We offer a comprehensive inventory of our in-house die library ready to immediately satisfy a broad range of production requirements, eliminating the cost for tooling. Our extensive supplier network enables us to source and negotiate bottom line pricing for a wide spectrum of raw materials. Our most popular rubber is black, however we are capable of extruding a range of colors. Our standard for rubber hardness is the Shore A Durometer Scale with ratings from 40 to 90 durometer. Our secondary services range in scope from notching and drilling to reverse engineering and sub-assembly, allowing you to eliminate the hassle of sourcing your project to multiple suppliers.

Arc Rubber provides industrial businesses with a wide range of quality, cost-effective rubber products with a quick turnaround for customers. We utilize an extensive lineup of production equipment to extrude your small, delicate parts in continuous lengths, as well as products as large as 12 inches in width and 10 feet in length. Molding presses complete our manufacturing lineup. Through the integration of our in-house tool shop, we are able to expertly manufacture new tooling and quickly alter your existing profiles to address sudden design modifications. We offer a comprehensive inventory of our in-house die library ready to immediately satisfy a broad range of production requirements, eliminating the cost for tooling. Our extensive supplier network enables us to source and negotiate bottom line pricing for a wide spectrum of raw materials. Our most popular rubber is black, however we are capable of extruding a range of colors. Our standard for rubber hardness is the Shore A Durometer Scale with ratings from 40 to 90 durometer. Our secondary services range in scope from notching and drilling to reverse engineering and sub-assembly, allowing you to eliminate the hassle of sourcing your project to multiple suppliers.

Dunnage is a term used to label the rubber inserts in racks that hold products in place and protect them for shipping or storage. The rubber provides a non-marring and anti-slip surface on which products rest. A major advantage of rubber is its resistance to wear. Other dunnage material, such as polyurethane, tends to “carve out” where the part meets the dunnage. Rubber on the other hand is very durable and typically less expensive. We extrude rubber dunnage so tooling is considerably less than other processes. Our in-house tool shop allows us to be very flexible in the changing of design and the simplicity in method means shorter lead time compared to molding methods. Arc Rubber produces several different styles of dunnage inserts includeing five basic types; Flat Rubber, P Rubber, Fluted Rubber, Notched Rubber and Notched Rubber on Steel Retainers.

Dunnage is a term used to label the rubber inserts in racks that hold products in place and protect them for shipping or storage. The rubber provides a non-marring and anti-slip surface on which products rest. A major advantage of rubber is its resistance to wear. Other dunnage material, such as polyurethane, tends to “carve out” where the part meets the dunnage. Rubber on the other hand is very durable and typically less expensive. We extrude rubber dunnage so tooling is considerably less than other processes. Our in-house tool shop allows us to be very flexible in the changing of design and the simplicity in method means shorter lead time compared to molding methods. Arc Rubber produces several different styles of dunnage inserts includeing five basic types; Flat Rubber, P Rubber, Fluted Rubber, Notched Rubber and Notched Rubber on Steel Retainers.

Arc Rubber produces high quality wheel chocks for everything from large rolls of steel or paper to trucks and aircraft. We have all the tooling and necessary resources in-house ready to run your job. Although there are many different chock profiles, the material for all is a high-grade rubber that will withstand multiple rollovers and outdoor climates. Many of our chocks are available with reflective tape, eyebolts for attaching ropes and/or solid braided multifilament polypropylene rope that is great in all climates. Our Wheel Chocks can be trimmed to the length needed for your application.

Arc Rubber produces high quality wheel chocks for everything from large rolls of steel or paper to trucks and aircraft. We have all the tooling and necessary resources in-house ready to run your job. Although there are many different chock profiles, the material for all is a high-grade rubber that will withstand multiple rollovers and outdoor climates. Many of our chocks are available with reflective tape, eyebolts for attaching ropes and/or solid braided multifilament polypropylene rope that is great in all climates. Our Wheel Chocks can be trimmed to the length needed for your application.

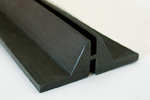

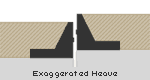

EZ Control™ is specifically designed to work with stone epoxy flooring by maintaining existing control joints. It reduces the hassles of using hard plastic strips that only come in one size and also eliminates backtracking to saw the laminate to match control joints in the substrate. EZ Control is produced from high quality EPDM formulation to endure extended outdoor applications. It is extruded in lengths up to 500 feet which eliminates many butt joints. Once installed, only 1⁄16 inch is visible from the top on each side of the joint. After slitting the webbing with a utility knife, it allows the laminate to move with the substrate.

EZ Control™ is specifically designed to work with stone epoxy flooring by maintaining existing control joints. It reduces the hassles of using hard plastic strips that only come in one size and also eliminates backtracking to saw the laminate to match control joints in the substrate. EZ Control is produced from high quality EPDM formulation to endure extended outdoor applications. It is extruded in lengths up to 500 feet which eliminates many butt joints. Once installed, only 1⁄16 inch is visible from the top on each side of the joint. After slitting the webbing with a utility knife, it allows the laminate to move with the substrate.